Spindle Bearing

Characteristics: The spindle bearing is a kind of single row angular contact ball bearing composed of solid inner ring, outer ring, ball and solid window retainer. The spindle bearing is inseparable. The bearing is designed to open and sealing type. The tolerance range of spindle bearing is very small; therefore they are very suitable for arrangement layout of highorientation accuracy and high speed working condition. It is proved that they are suitable for bearing arrangement of machine tool spindle.

Radial and axial bearing capacity: The spindle bearing can bear single axial force and radial force. The spindle bearing in O-type and X-type arrangement can bear bidirectional bearing force and moment of force. The spindle bearing in tandem arrangement can only bear axial force at single direction. The contact angle of spindle bearing can be 15°C (with the suffix of C) or 25°C (with the suffix of E).

Standard spindle bearing: B70, B719 and B72 series of standard spindle bearings adopt steel balls as rolling element.

Ceramic ball: HCB70, HCB719 and HCB72 of spindle bearings adopt standard ceramic balls as rolling element (which is also called hybrid bearing)

Sealing: B70..-2RSD, B719..-2RSD, B72..-2RSD, HCB70..-2RSD, HCB719..-2RSD and HCB72..-2RSD series of spindle bearing is provided with gap sealing at both sides.

Lubricating: Sealed bearing is lubricated by Krupplubricating grease of high quality for free.

High speed spindle bearing: the steel ball dimension of HSS70 and HSS719 series of high speed spindle bearing is smaller than standard dimension.

Ceramic ball: In addition, HSS70 and HSS719 series of high speed spindle bearing adopt ceramic ball (hybrid bearing). The four series of bearings are featured by its high revolving speed, less friction and heating, therefore, it is not easy to get lubricating agent being aged so as to prolong the operating life.

Sealing: These bearing can equipped with gap sealing at both sides. Open HS70, HS719, HC70 bearing and HC719 bearing are provided.

Lubrication: Sealed bearing is lubricated by Krupplubricating grease of high quality for free.

Operating temperature: Limited by seal ring and material of retainer, the operating temperaturesuitable for bearing is from -30°C to +100°C. The operating temperature range of standard grease used for sealed spindle bearing is +80°C. When selecting lubricating agent, the operating temperature must be considered.

Retainer: The retainer of spindle bearing with solid window retainer is made from reinforced fiber (with the suffix of T). The retainer is guided by outer ring. Check chemical stability of seal ring and retainer material on synthetic grease and lubricating agent with EP extreme pressure additive. Under high temperature, aged lubricating oil and additive in the oil will reduce operating life of nylon retainer. Therefore, it must strictly follow the replacement cycle of lubricating oil.

Suffix: existing design

|

Series |

Suffix |

Description |

Design |

|

B719, B70, B72 |

C |

Contact angle15° |

Standard design |

|

E |

Contact angle25° |

||

|

HCB719 HCB70 HCB72 |

H |

Heavy preload 1) |

|

|

L |

Light preload 1) |

||

|

M |

Medium preload 1) |

||

|

HSS719 HSS70 |

P4S |

Grade of tolerance P4S |

|

|

T |

Reinforced fiber solid window retainer |

||

|

HCS719 HCS70 |

UL |

All-purpose paired bearing, under condition of X-type or O-type arrangement, light preload is provided for bearing. |

|

|

2RSD |

Gap sealing at two sides. (B series and HCB series) |

1) For pretightening force, refer to ultra-precise bearing sample AC41 130.

Static load safety factor: We introduce static load safety factor SO0>3 to maintain the bearing accuracy.

COr: N

Basic rated load, like equivalent weight static load in the dimension.

P0: N

If there are many bearings, the external force is distributed in each bearing. For more information, please look up bearing sample AC41 130.

Revolving speed: the revolving speed of bearing arrangement is decided by the following factors:

█ preload of bearing

█ whether the bearing is in elasticity arrangement or rigidity arrangement in main shaft

█ whether the bearing is installed one by one or in pairs

█ lubricating agent

█ cooling of bearing

All-purpose paired bearing pack: all-purpose bearings (with the same pore diameter and outer diameter) with the same type can be used in pairs. They can be used in various pairs (O-type and X-type tandem arrangement). The codes of bearing packs of light preload are as follows:

█ double (two sets of bearings) with the suffix of DUL

█ triple (three sets of bearings) with the suffix of TUL

█ quadruple (four sets of bearings) with the suffix of QUL

Order data: When bearing is ordered, the quantity of bearing pack rather than that of single bearing must be indicated.

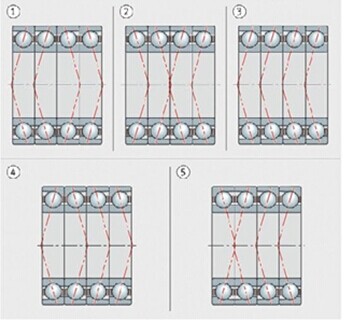

Install-and-play bearing pack: in install-and-play bearing pack, bearings can be provided in specific arrangement mode. The bearing must be installed according to the ordered arrangement mode.

Figure 1 Double Bearing Pack:①DBL, O-type arrangement

②DFL, X-type arrangement

③DTL, tandem arrangement

Figure 2 Triple Bearing Pack: ①TBTL, combination of O-type arrangement and tandem arrangement

②TFTL, combination of X-type arrangement and tandem arrangement

③TTL, tandem arrangement

Figure 3 Quadruple Bearing Pack:①QBCL, O-type arrangement

②QFCL, X-type arrangement

③QTL, tandem arrangement

④QBTL, combination of O-type arrangement and tandem arrangement

⑤QFTL, combination of X-type arrangement and tandem arrangement

Order example: Description of 1-HSS7012-C-T-P4S-DBL: two bearings in O-type arrangement and light preload.

Design of bearing arrangement

Shaft and bearing pedestal tolerance: for the spindle bearing and relevant description of cooperation and speed, refer to ultra-precise bearing sample AC 41 130.

Installation dimension: maximum chamfering radius dimension ra and ra1 and of adjacent structure and shoulder diameter Da and da of adjacent structure.